Voltage Available: 110V/120V or 220V/230V

- 30W Soldering Iron

- 3 Nickel Plated Soldering Tips

- Solder Paste in Plastic Can

- Solder Wire in Plastic Tube

- De-Soldering Pimp (Aluminum)

- Mini-Iron Stand with Sponge

- Electrical Insulation Tape 19mm X 9m

- "-" Standard Cicuit Tester

- "+" 4mm Dia. Philip Screwdrive in plastic handle

- "+" 5mm Dia. Philip Screwdrive in plastic handle

- "-" 5mm Dia. Standard Screwdrive in plastic handle

- 125mm Long Nose Pier

- 125mm Plastic Nipper

- Wire Stripper (for wire 0.2 - 6.0mm)

- Scrap

Soldering Equipment

The Soldering Iron/Gun

The first thing you will need is a soldering iron, which is the heat source used to melt solder. Irons of the 15W to 30W range are good for most electronics/printed circuit board work.

A 30W Watt Soldering Iron

Solder The choice of solder is also important. There several kinds of solder available but only a few are suitable for electronics work. Most importantly, you will only use rosin core solder. Acid core solder is common in hardware stores and home improvement stores, but meant for soldering copper plumbing pipes and not electronic circuits. If acid core solder is used on electronics, the acid will destroy the traces on the printed circuit board and erode the component leads. It can also form a conductive layer leading to shorts.

Kester For most printed circuit board work, a solder with a diameter of 0.75MM to 1.0MM is desirable. Thicker solder may be used and will allow you to solder larger joints more quickly, but will make soldering small joints difficult and increase the likelihood of creating solder bridges between closely spaced PCB pads. An alloy of 60/40 (60% tin, 40% lead) is used for most electronics work. These days, several lead-free solders are available as well. Kester "44" Rosin Core solder has been a staple of electronics for many years and continues to be available. It is available in several diameters and has a non-corrosive flux.

Large joints, such as soldering a bracket to a chassis using a high wattage soldering gun, will require a separate application of brush on flux and a thick diameter solder of several millimeters.

Remember that when soldering, the flux in the solder will release fumes as it is heated. These fumes are harmful to your eyes and lungs. Therefore, always work in a well ventilated area and avoid breathing the smoke created. Hot solder is also dangerous. It is surprisingly easy to splash hot solder onto yourself, which is a thoroughly unpleasant experience. Eye protection is also advised.

Preparing To Solder

Tinning The Soldering Tip Before use, a new soldering tip, or one that is very dirty, must be tinned. "Tinning" is the process of coating a soldering tip with a thin coat of solder. This aids in heat transfer between the tip and the component you are soldering, and also gives the solder a base from which to flow from.

Step 1: Warm Up The Iron

Warm up the soldering iron or gun thoroughly. Make sure that it has fully come to temperature because you are about to melt a lot of solder on it. This is especially important if the iron is new because it may have been packed with some kind of coating to prevent corrosion.

Step 2: Prepare A Little Space

While the soldering iron is warming up, prepare a little space to work. Moisten a little sponge and place it in the base of your soldering iron stand or in a dish close by. Lay down a piece of cardboard in case you drip solder (you probably will) and make sure you have room to work comfortably.

Step 3: Thoroughly Coat The Tip In Solder

Thoroughly coat the soldering tip in solder. It is very important to cover the entire tip. You will use a considerable amount of solder during this process and it will drip, so be ready. If you leave any part of the tip uncovered it will tend to collect flux residue and will not conduct heat very well, so run the solder up and down the tip and completely around it to totally cover it in molten solder.

Step 4: Clean The Soldering Tip

After you are certain that the tip is totally coated in solder, wipe the tip off on the wet sponge to remove all the flux residue. Do this immediately so there is no time for the flux to dry out and solidify.

Cleaning off excess solder and flux

Soldering A Wire Joint or Splice

Another very common task is soldering a joint between two or more wires. Unlike soldering a PCB where the component is generally held only by the solder joint itself, a splice between wires must be physically strong before it is soldered. This usually means twisting the wires together properly and then soldering. Areas where you will see soldered wire joints are cable repairs and automotive wiring. In these cases, the joint must be insulated after soldering as well.

- Step 1: Strip The Wires To Be Joined, Slip On Insulation

- Heat shrink tubing is generally the preferred method to insulate a wire splice. There are two main types of heat shrink available; adhesive lined and non-adhesive lined. Non-adhesive tubing forms an insulating barrier only and thus is suitable for use only when the joint will not be subjected to moisture, chemicals or other harsh environments. Adhesive lined heatshrink tubing is lined with a heat sensitive adhesive that melts to seal the joint as the tubing is heated. Thus it forms a totally sealed joint and is used when a splice will be subjected to moisture or other elements which can effect the joint. As an example, you would use non-adhesive shrink tube when repairing a lamp cord, but you would use adhesive lined tubing when installing a car stereo.

Use heat shrink tube with a diameter of approximately 1.5 times to two times the diameter of the wires to be joined. Cut the tube to length so that it will extend past each side of the joint by at least 0.5 inches and then slip it over one of the wire ends.

Now strip about an inch of insulation from each wire end. If you are joining rather thick wire (thicker then 12 gauge) then you may want to strip a little more insulation to make twisting the wire easier.

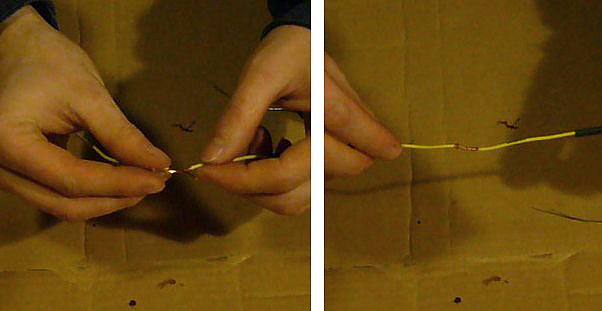

- Step 2: Twist The Wires Together

- A strong mechanical connection is necessary before the wires are to be soldered so you must twist them together. The wires will be twisted in what is referred to as a "Lineman's joint" where the wires are joined in a straight line as opposed to twisting together in a "V" shape.

Hold the stripped ends of the wires together in an "X" shape so their middles cross one another and then twist one of the wires along the other wires length. Then twist the other side to match. What you will end up with is a strong wire joint that is generally not much thicker then the wire itself.

- Step 3: Apply Heat

- Apply your heat to the bottom of the wire joint and use the thicker section of the soldering tip. If you heat up the top of the wire, you will get a lot of heat loss since heat rises. The thicker area of the solder iron tip will conduct more heat into the wire joint. It also helps to slightly wet the tip of the soldering iron to further aid in heat transfer. The thicker the wire joint, the more heat will be required. Be careful, because on thin wires with cheap insulation you can actually melt quite a bit of it off if you overheat the joint. Once the joint is hot enough (a good clue is when the solder you used to wet the tip of the iron flows into the joint) you can move on to applying solder.

Once you have soldered a number of these joints you will be able to judge how much heat must be applied based on the thickness of the wire.

- Step 4: Apply Solder To The Joint

- With the joint fully heated, apply your solder to the joint just above the soldering tip. If it doesn't begin to melt immediately then you will need more heat. Once the solder begins to melt it will flow into the joint around the soldering iron. As the solder flows, move the tip along the wire joint while applying solder. The joint should start to suck in the solder as it is applied. If you find that the solder is pooling where it is touched to the joint yet it is not flowing inside, you will need more heat. Continue adding solder until the joint is fully covered. You should still be able to see the outlines of the individual wire strands but no copper of the wire should be visible. If you add too much solder to the point where the joint becomes a blob, you will end up with a brittle joint and the excess solder will need to be removed.

- Step 5: Clean The Flux

- If the wire joint is to be sealed or used in an area it will be exposed to moisture, the flux must be removed. Some fluxes will absorb moisture or other chemicals and become corrosive to the joint. While there are flux removal chemicals available most fluxes can be cleaned up using methyl hydrate available at any hardware store. Some are even water soluble.

- Step 6: Insulate The Joint

- Slide the heat shrink tubing so that it evenly covers the joint and apply heat to shrink it. Ideally, you will want a heat gun for this but a simple lighter is acceptable as long as you keep the flame moving to avoid burning the tubing or the wire. If you used adhesive lined heat shrink, you need to heat the tube until it has shrunk fully around the wire and a little of the adhesive has oozed out the ends. Non-lined heatshrink can be heated until it tightly covers the joint. You can overheat this stuff. If too much heat is used, then the insulation underneath will begin to break down and may form a bubble. A bubble could also be caused if you heat adhesive lined tubing to the point where it starts to boil.

- You're Done! Now Just Watch The Video

- That's it! Your wire joint is now complete. You can watch the process on video below:

Tips and Tricks

Soldering is something that needs to be practiced. These tips should help you become successful so you can stop practicing and get down to some serious building.

- Use heatsinks. Heatsinks are a must for the leads of sensitive components such as ICs and transistors. If you don't have a clip on heatsink, then a pair of pliers is a good substitute.

- Keep the iron tip clean. A clean iron tip means better heat conduction and a better joint. Use a wet sponge to clean the tip between joints. Keep the tip well tinned.

- Double check joints. When assembling complicated circuits, it is good practice to check joints after soldering them. Use a magnifying glass to visually inspect the joint and a meter to check resistance.

- Solder small parts first. Solder resistors, jumper leads, diodes and any other small parts before you solder larger parts like capacitors and transistors. This makes assembly much easier.

- Install sensitive components last. Install CMOS ICs, MOSFETs and other static sensitive components last to avoid damaging them during assembly of other parts.

- Use adequate ventilation. Most soldering fluxes should not be breathed in. Avoid breathing the smoke created and make sure that the area you are working in has adequate airflow to prevent buildup of noxious fumes.

Soldering Safety

While soldering is not generally a hazardous activity, there are a few things to keep in mind. The first and most obvious is that it involves high temperatures. Soldering irons are going to be 350F or higher, and will cause burns very quickly. Make sure to use a stand to support the iron and keep the cord away high traffic areas. Solder itself can drip, so it makes sense to avoid soldering over exposed body parts. Always work in a well lit area where you have space to lay parts out and move around. Avoid soldering with your face directly above the joint because fumes from the flux and other coatings will irritate your respiratory tract and eyes. Most solders contain lead, so you should avoid touching your face while working with solder and always wash your hands before eating.

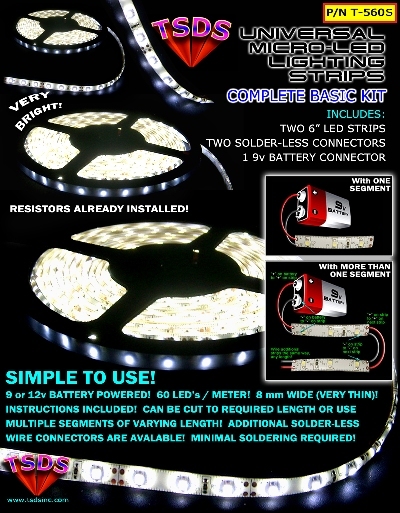

"A Complete basic starter kit for LED strips."

This starter kit comes with 2 six-inch white LED strips (9 LED's on each strip, NO RESISTORS OR MATH REQUIRED!), a 9-volt battery connector, and two SOLDER-LESS connectors! Easy to use! You can link the two strips together via some wire, or use them in two different model kits.

They create a LOT of light, and have 3M adhesive on the back side!

Longer lengths (12" and 36") are available, as well as extra SOLDER-LESS connectors.

- LEDS

- Resistors

- Wires

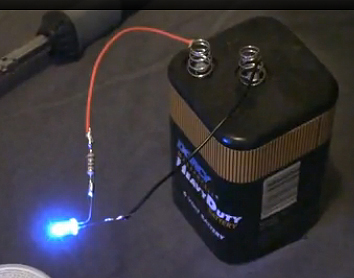

- testing battery

- soldering gun

- Heavy Duty 9 Volt Battery Snap

- Mini On/Off Switch or On-Off Button

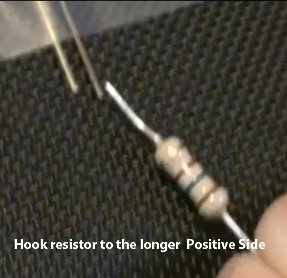

The longer/thinner wire on the LED is the POSITIVE SIDE.

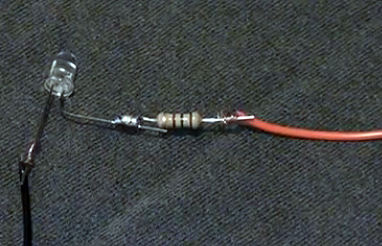

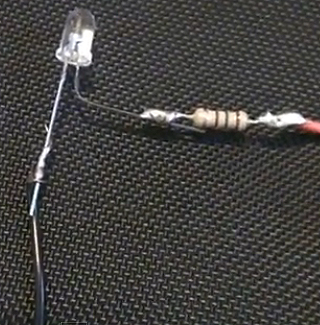

Solder the resistor to the POSITIVE SIDE

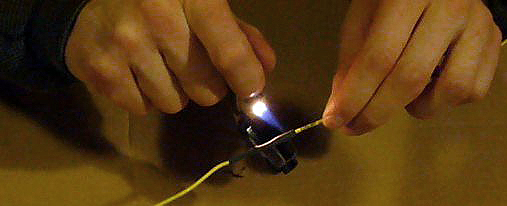

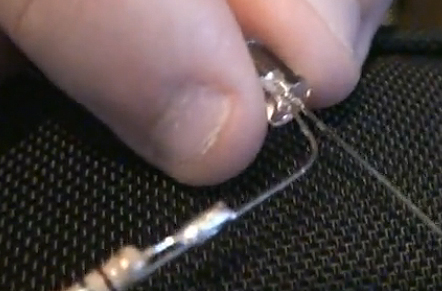

Example of solder joint.

Solder the resistor to the POSITIVE WIRE

Solder the LED to the NEGATIVE WIRE

Test

On-Off Button Examples

2 x Snap on 9V Volt Battery Clip Connector I Type Black

$1.99 free shipping