Constructing a Simple Mold Box/Materials

The purpose of a mold box is to contain the liquid rubber (after it is poured over and around a model) until the liquid turns to a solid. A mold box does not have to be a complex structure –depending on the size and configuration of your model, often a coffee can, cake pan or plastic bucket will suffice. If you make molds of flat – two dimensional models on a regular basis and require a mold box there are a number of advantages in constructing your own mold box.

- Advantages of Constructing A Mold Box

- Easy To Construct

- Minimal Assembly Required

- Reusable

- Adjustable (to adapt to different size models)

Dimensions: 15" long x 10.5" wide x 1" tall (38 cm x 27 cm x 2.5 cm)

Flat Baseboard -- (Plywood or Acrylic Sheeting)

Dimensions: 20" long x 16" wide x ˝ " thick (51 cm x 41 cm 1.3 cm)

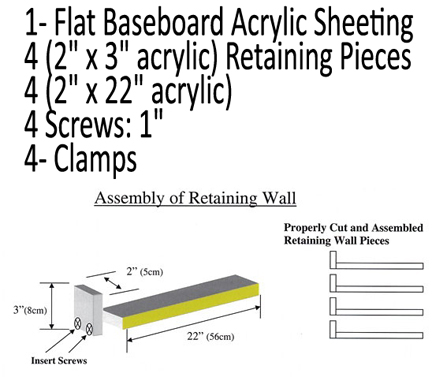

Retaining Pieces— (4) 2" x 3" (5 cm x 7.6 cm pieces of wood or acrylic)

(4) 2" x 22" (5 cm x 56 cm pieces of wood or acrylic)

Screws: 1" (2.5 cm) Clamps

Modeling Clay or hot melt glue gun,

Smooth-On Super Instant Epoxy.

Assembly :

| Step 1. | Cut and Assemble Retaining Walls To accommodate our model, we have constructed retaining walls out of ˝" (1.3 cm) thick acrylic strips. We selected acrylic because most mold rubbers release easily from acrylic. Wood can also be used. Four pieces measuring 2" x 3" (5 cm x 7.6 cm) were cut for the shorter side of the retaining wall and four 2" x 22" (5 cm x 56 cm) pieces were cut for the longer side of the retaining wall. These pieces were then assembled together in an "L" shape with 1" (2.5 cm) screws. (See Figure One Below). |

| Step 2. | Secure Model To Baseboard The baseboard should be at least twice the size of the original model to allow enough "working space". Secure the model to the backboard by applying a bead of hot melt glue around the perimeter of the reverse side of the model. Press model firmly onto baseboard and create a tight seal where the model meets the baseboard. This will prevent liquid rubber from leaking underneath the model. |

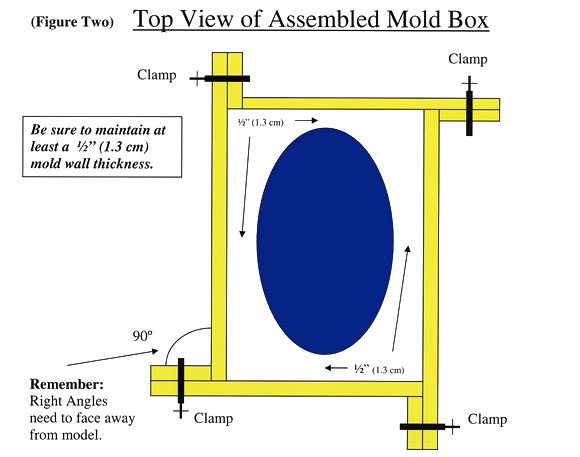

| Step 3. | Assemble Retaining Walls Around Model Place retaining pieces around the model, making certain there is at least a ˝" (1.3 cm) clearance (gap) between the cameo and retaining wall. This ˝" (1.3 cm) gap will equal the wall thickness of the cured rubber mold. (Figure Two) |

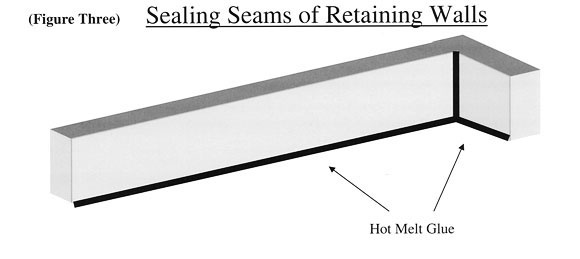

| Step 4. | Clamp Retaining Walls Together Fasten the retaining walls together with C-clamps and apply hot melt glue to any seams where the liquid rubber may leak out. This includes seams where the retaining walls meet the baseboard and also where retaining walls meet one another. Important: Mold box seams not properly sealed will result in rubber leakage — which equals lost time, dollars and material. (Figure Three) |

| Step 5. | Apply Sealer To Model: Smooth-On SUPERSEAL. Being made of terra cotta, the cameo and any other porous model must be sealed. Models made of water/sulfur based clays must also be sealed as well. Apply 2 coats of SuperSeal to entire model and surrounding forms (let first coat dry 7 minutes before applying next coat, letting final coat dry for at least 1 hour). |

| Step 6. | Apply Release Agent – Smooth-On Universal Mold Release. For easiest release, apply Universal Mold Release after SuperSeal is dry. Spray a light mist coating over surface of model and surrounding forms. Brush over surface and into areas of detail. Follow with another light mist coating and let dry for 15 minutes before applying rubber. |

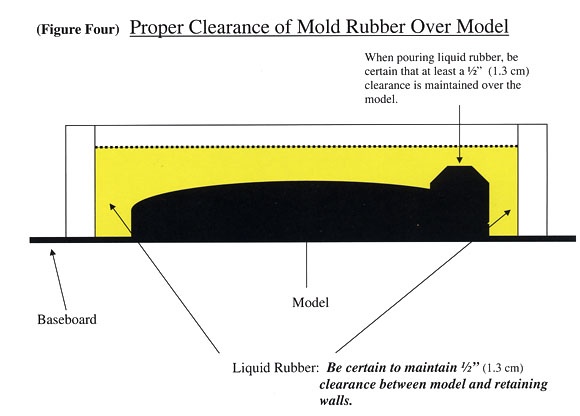

| Step 7. | Pour Mold Rubber Mix and pour mold rubber onto model and let cure. Be certain that the liquid rubber levels off at least ˝" (1.3 cm) above the highest point on the model. Let rubber cure overnight. |

| Step 8. | Removal of Retaining Walls. Finally, after rubber has cured, remove the retaining walls away from the cured mold and flex rubber mold to remove original model. (Figure Four) |

| Step 9. | Demold. Remove cameo from the cured rubber. |

Adjust-A-Mold Box

$39.00

-Link to Purchase a Box-

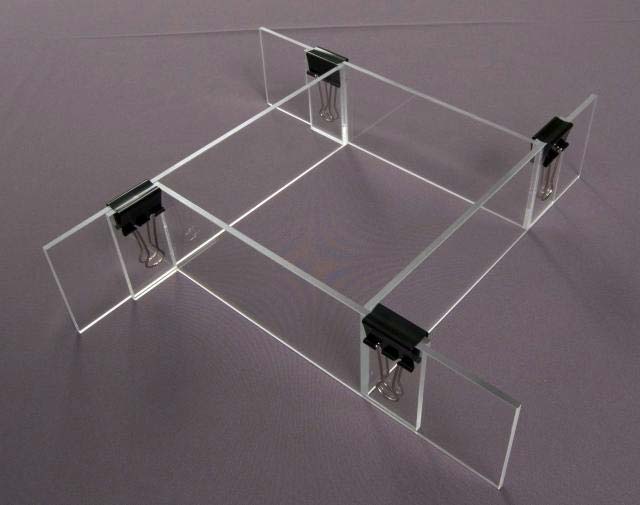

Our Adjust-A-Mold Box provides the reliability that is required when a mold is being made with some added convenience. The Adjust-A-Mold Box can be configured into many different sizes to custom fit a variety of molds up to 10" L x 10" W x 3" H. This amazing tool can be used over and over again, eliminating the need to purchase or build separate mold boxes. The Adjust-A-Mold Box includes 4 "L" shaped acrylic sides and 4 spring clips.

Using Safe-D-Clay apply a clay seal around the outside bottom and up the corners of the Adjust-A-Mold Box in order to make the Adjust-A-Mold Box water tight.

Directions for Building your own box.